Regeneracija Non-wovens and reGALLERY on 18th December 2024

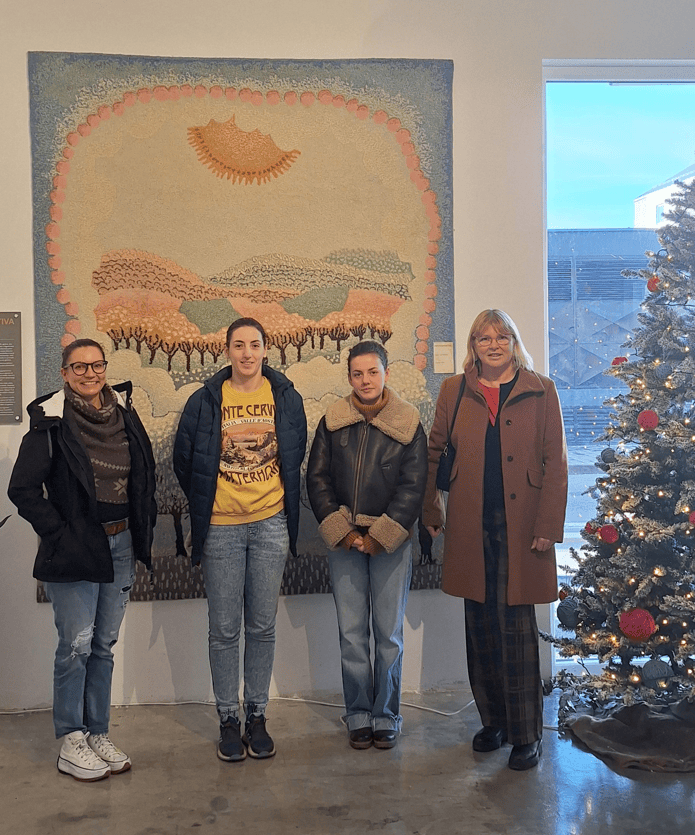

Prof. Sandra Bischof and Assist. Prof. Zorana Kovačević, together with Klarisa Čop and Lea Beličev, students of the 2nd year of the Textile Technology and Engineering (TTI) Master degree program, majoring in Textile Chemistry, Materials & Ecology (TKME), visited the plants of the RGNC Group – reGALLERY and Regeneracija Non-wovens.

Figure 1: Zorana Kovačević, Lea Beličev, Klarisa Čop i Sandra Bischof in exhibitoon space of reGalery

The company to produce non-woven textiles with headquarters in Zabok was founded in 1954, as a new facility within the Zagorje Woolen Fabric Industry (ZIVT). After 1955, the plant was separated and began to operate as an independent company „Regeneracija Prva jugoslavenska industrija netkanih tekstila“ (The first Yugoslavian non-woven textile industry). Until 2023, the company operated under the name Regeneracija, and today it operates as a holding company RGNC Group. The group consists of Regeneracija Non-wovens (dedicated to recycling of textile waste) and reGalerija (dedicated to production of woolen carpets using the manual tufting process). The emphasis is placed on socially responsible business, sustainability and ecological design. ISO 9001, 14001 and 45001 quality systems are applied in all production processes.

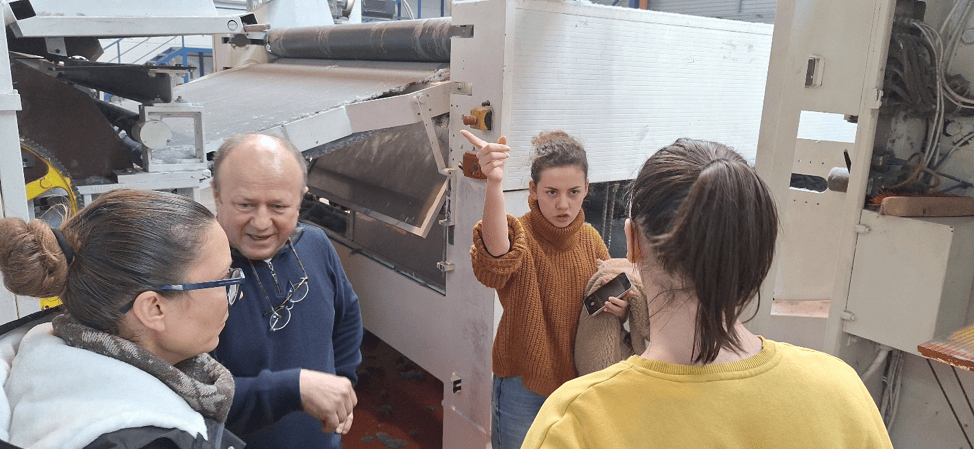

The main activity of Regeneracija Non-wovens is the recycling of textile waste, and the company operates according to the principle of a circular economy, which includes a complete closed value chain consisting of waste collection, sorting, production of non-woven technical textiles and distribution. After the completion of all production operations, which include initial mixing of different categories of waste and bicomponent fiber, separation of metal parts, loosening and separation of dust, antistatic treatment, treatment on the drag machine, laying and paralelisation of the nonwovens, calendering, the final treatment of the nonwoven textile is carried out. During the final treatment, the non-woven material is sprinkled with ethylene vinyl acetate (EVA) powder when passing through an IR heated area, which causes the powder to melt and connect nonwoven material with the plastic film, resulting in a high-quality product made of almost 100% recycled materials.

Figure 2: The production process of Regeneracija Non-Wovens

Currently, only 15% of applied textile waste represents the share collected in Croatia, which can certainly be increased in the future, especially after the entry into force of the legislative act on 1st January 2025, which introduces the obligation of separation and collection of postindustrial and households textile waste.